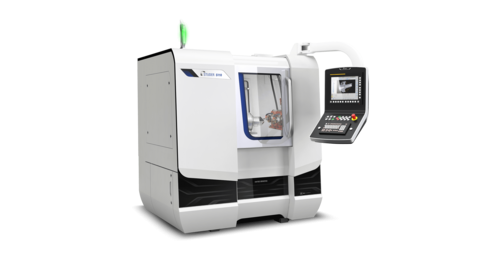

S110

The S110, a different very compact machine concept. The workpiece is moved on the cross-slide, while the grinding spindles are mounted in a fixed position to the base of the machine. This guarantees stability, offers good accessibility for set-up or workpiece change, and is easily automatable. The spindle set-up, with up to 3 HF grinding spindles in a linear arrangement, can be optimally designed to meet customer requirements. The ideal machine for chuck applications for individual components up to small-batch production. A cost-effective solution for high-precision automated grinding can be achieved with the optional, fully integrated automatic loading and unloading system.

Specifications

- Up to three HF grinding spindles in a linear arrangement

- Large selection of internal and external spindles (external wheel up to Ø 300mm)

- C axis for the workhead for form and thread grinding

- Manual A axis for precise thread grinding

- Compact and user-friendly

- Various dressing options

- Full enclosure with sliding door

- Integrated or autonomous loading systems

- Measuring probe

- SimCT offline simulation software

- Dovetailed work table for simple positioning of the grinding spindles (option)

- CNC-controlled Y-axis (vertical)

- Wide range of clamping devices and accessories

- Standardized interface for loader and peripheral devices