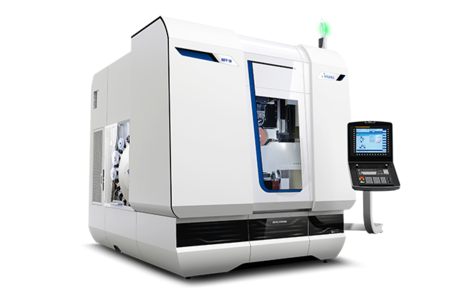

MFP 50

Form when dealing with challenging workpieces. The high axis speed, minimal auxiliary times and quick tooling change make the MFP 50 one of the most productive machines of its kind.

The Productive Machine

Processes such as grinding, cutting and drilling can be achieved to absolute perfection in a single clamping. High productive benefit with simple operation are the result. The intelligent design principle takes production quality, safety and cost efficiency to a new level. The coolant nozzle, controllable via two axes, allows unrestricted freedom of movement and precise positioning of the coolant jet.

Spindle speeds of up to 10 000 revolutions per minute guarantee the highest machining precision.The grinding wheels are always mounted right at the front of the spindle, and the profile is changed through automatic positioning of the diamond rolls in the direction of the Z-axis. This allows a generous machining clearance, as collisions between wheel flange and workpiece are practically excluded.

In the MFP 50 the grinding wheel diameter is used to the maximum, resulting in significant cost savings.

Specifications

| Linear Axes | |

|---|---|

| Max. Travel X | 500 mm |

| Max. Travel Speed X | 30,000 mm/min |

| Max. Travel Y | 650 mm |

| Max. Travel Speed Y | 20,000 mm/min |

| Max. Travel Z | 650 mm |

| Max. Travel Speed Z | 20,000 mm/min |

| Spindle Drive | |

| Max. Spindle Power | 50 kW |

| Max. Number of Revolutions | 10,000/ min |

| Max. Grinding Wheel Diameter | 300 mm |

| Max. Grinding Wheel Width | 60 mm |

| Swiveling Axes | |

| Swiveling Range A | 210° |

| Swiveling Range B | 360° |

| Swiveling Range C | 360° |

| Workpiece Data | |

| Table Size | 500 x 650 mm |